Optimizing Factory Design and Operations with Digital Twin Technology

What is Digital Twin?

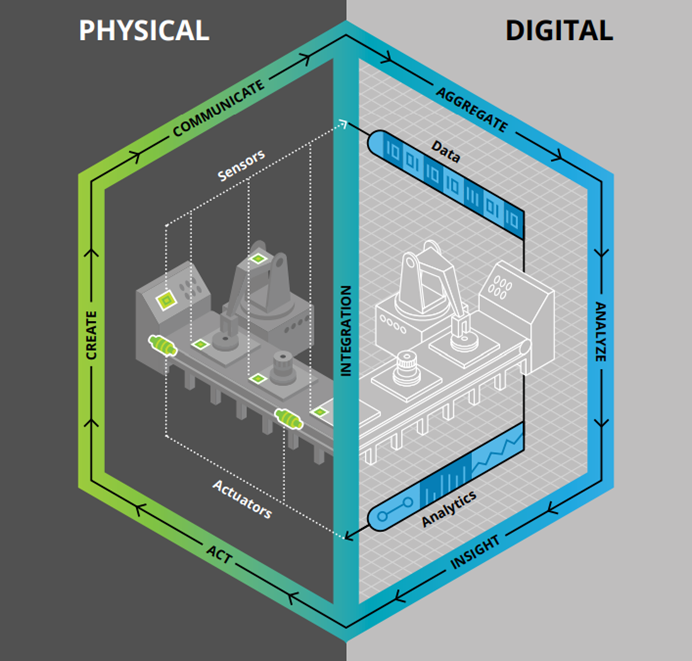

A Digital Twin in factory design and Industry 4.0 is a dynamic virtual model of a manufacturing system or process, integrating real-time IoT data, analytics, and AI to replicate real-world behavior. It enables simulation, optimization, and smarter decision-making, playing a vital role in creating adaptive and efficient smart factories.

Digital twin business values

Quality

• Improve overall quality

• Predict and detect quality trend defects sooner

• Control quality escapes and be able to determine when quality issue started

New product introduction cost and lead time

• Reduce the time to market for a new product

• Reduce overall cost to produce new product

• Better recognize long-lead-time components and impact to supply chain

Operations cost

• Improve product design and engineering change execution

• Improve performance of manufacturing equipment

• Reduce operations and process variability

Revenue growth opportunities

• Identify products in the field that are ready for upgrade

• Improve efficiency and cost to service product

Integrating Virtual Reality (VR) with Digital Twin Technology

Integrating Virtual Reality (VR) with Digital Twin technology creates an interactive simulation environment where users can explore and interact with virtual models in real-time. By utilizing sensor data and AI-driven analysis, VR headsets display dynamic models that accurately reflect the actual state of the system.