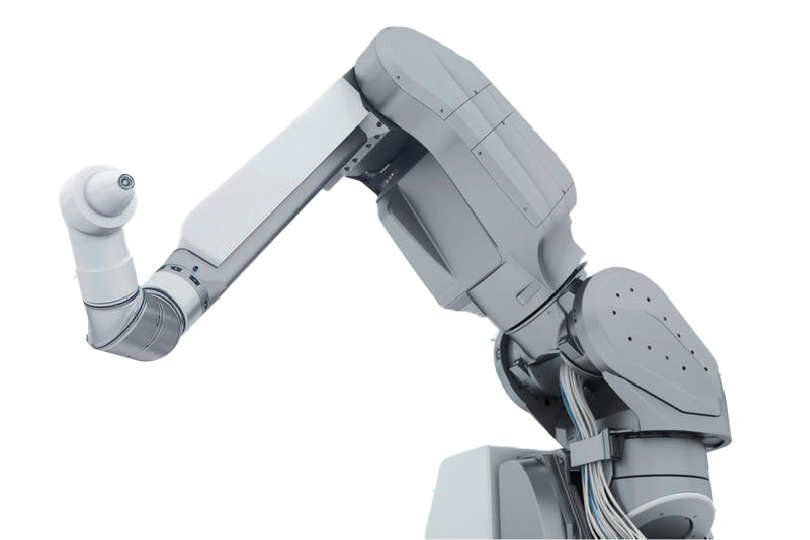

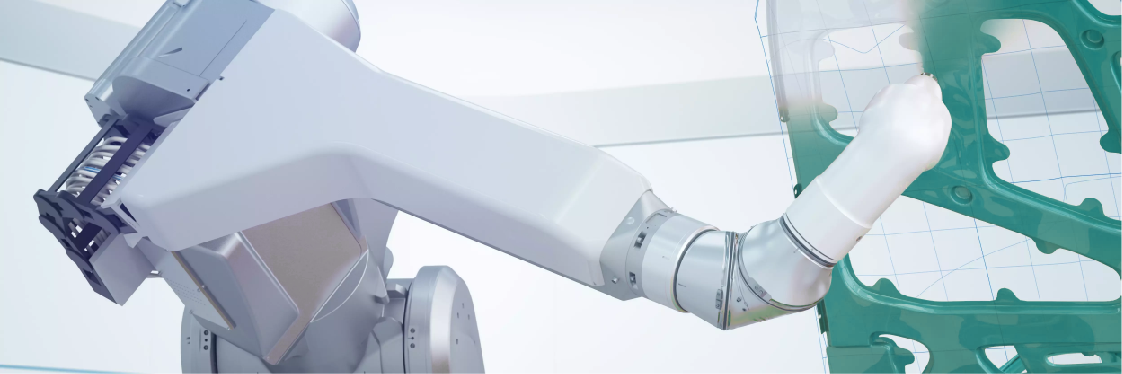

PAINTING ROBOT

Cyber Provides Wide Range Of Robotic Painting Solutions For FA (Factory Automation) Painting Processes

Cyber can provide painting robots that are suitable for your painting process requirements,

which we will study and re-design to fabricate the appropriate industrial robotic arm to achieve

that process automatically!

Do More, Do It More Repeatably:

Advantages Of Using Painting Robots

-Improved safety in hazardous painting work environments.

-Consistent robotic paint application significantly reduces material waste.

-Higher product speeds and productivity.

-Speed up painting process.

Industries That Use Painting Robots

Painting robots are used in wide range of industrial painting solutions, for several products

types, as the high-volume products and the products that are needed to be painted precisely

with high-quality finishing.

Types Of Painting Robots

We can divide the painting robots into several types according to many factors, for example,

the mounting and fixing method of the industrial robotic arm, and the type of used painting

technology.

How Painting Robots Are Mounted

The Four Main Ways Of Installing Painting Robots Are:

-Floor – takes up the most space but is easiest to integrate into a painting booth.

-Ceiling – requires less space than floor mounting but is more complicated and expensive.

-Wall – also takes up less floor space than floor mounting. Care must be taken to

accommodate the dynamic forces.

-Rail or Overhead Gantry – enables the painng robot to move backward and forward over

large distances. Can paint exceptionally large objects like airplanes, trucks, and railroad car.

Most Common Used Painting Technologies:

Air spray – a stream of air is mixed with the coating to break the fluid into fine droplets.

Most common for paints.

Ultrasonic spray – an atomization surface vibrates at an ultrasonic frequency.

The coating hitsthe vibrating surface and is turned into a fine mist. Used to apply insulation

and conductive films on small products. Other uses include anti-glare coatings, photoresist,

and various coatings with special properties.

Electrostatic – the coating fluid is charged with thousands of volts of static electricity

in the nozzle. Electrostatic repulsion turns the liquid into a mist. The mist is atiracted to the

surface to be coated by an opposite electrical charge. With this method, an even coating can be

applied to uneven surfaces. The efficiency is remarkably high, with litile paint wasted.

CYBER’S ENGINEERS WILL PUT YOU ON THE RIGHT

PATH TO MAKE YOUR PAINTING PROCESS

MORE EFFECTIVE!

COMPLETED SOLUTIONS

ASSESSMENT AND PLANNING

SIMULATING AND PROGRAMMING

EXPERT MANUFACTURING AND FABRICATION

BEAM SAW MACHINE

INDUSTRIES THAT USED OUR ROBOTICS SOLUTIONS

AUTOMOTIVE INDUSTRY

LOGISTICS AND WAREHOUSING

METAL FABRICATION INDUSTRY

FOOD AND BEVERAGE INDUSTRY