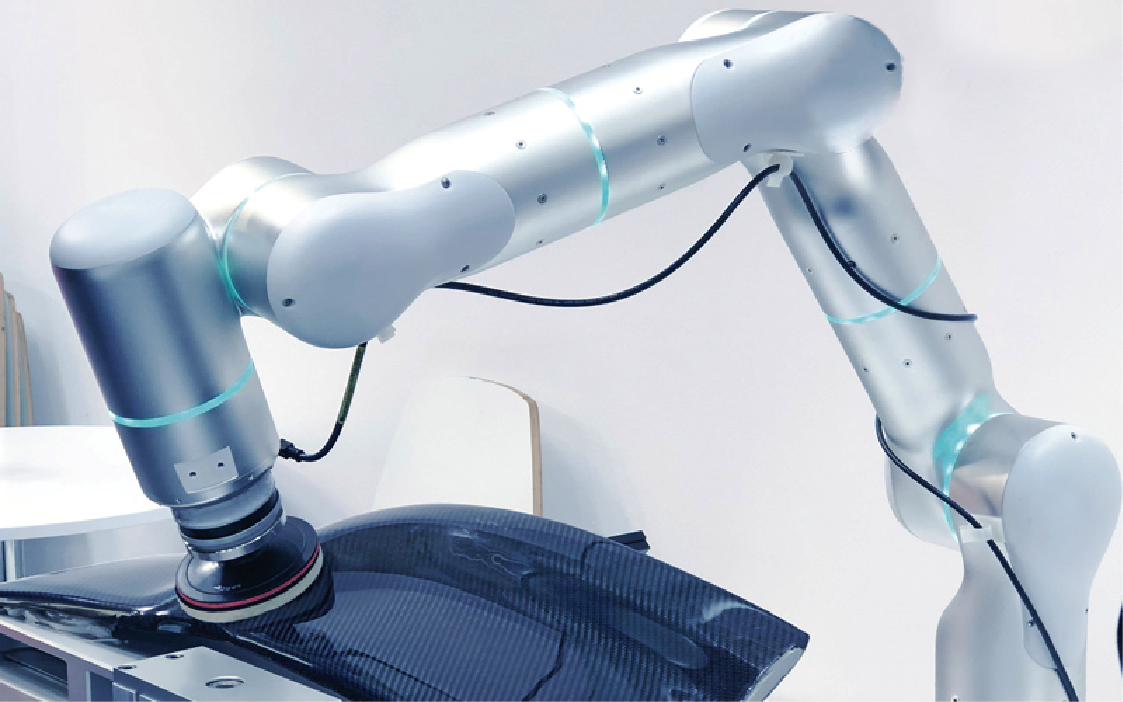

Polishing ROBOT

CYBER Can Automate Your Finishing Process By

Polishing Robots!

CYBER can improve and speed up your finishingprocess.Automating polishing applications is

highly effective since they entail standardized tasks with repetitive characteristics.

Employing Automated Polishing Is A Proficient Method For

Enhancing Both Throughput And Part Quality!

Polishing stands as a critical factor in elevating part quality, safety, and overall presentation.

As the final step before parts are packaged and shipped, it represents manufacturers’ last chance to ensure the excellence of their products. Widely recognized as one of the most

Prevalent finishing tasks, polishing delivers a smooth surface, consistent luster,

and impeccable finish, free from any imperfections.

Which Polishing Tasks Suit Robots?

Polishing tasks stand out as ideal candidates for automation due to their standardized nature and repetitive characteristics. Manufacturers dealing with high-volume part production are prime contenders for adopting polishing automation. Processes such as buffing and finishing encompass standardized steps that lend themselves well to robot programming. Any deviations in parts can be effectively managed through strategic programming, as will be briefly

Explored in the challenges section.

Industries That Use Polishing Robots

Industries that employ polishing robots span a wide range, including, Automotive: Polishing

robots are used to enhance the finish of car bodies and parts, ensuring a flawless appearance,

as well as Electronics Manufacturing, Medical sector and many other industries.

COMPLETED SOLUTIONS

ASSESSMENT AND PLANNING

SIMULATING AND PROGRAMMING

EXPERT MANUFACTURING AND FABRICATION

BEAM SAW MACHINE

INDUSTRIES THAT USED OUR ROBOTICS SOLUTIONS

AUTOMOTIVE INDUSTRY

LOGISTICS AND WAREHOUSING

METAL FABRICATION INDUSTRY

FOOD AND BEVERAGE INDUSTRY