Palatalizing ROBOT

Transforming Packaging Efficiency with

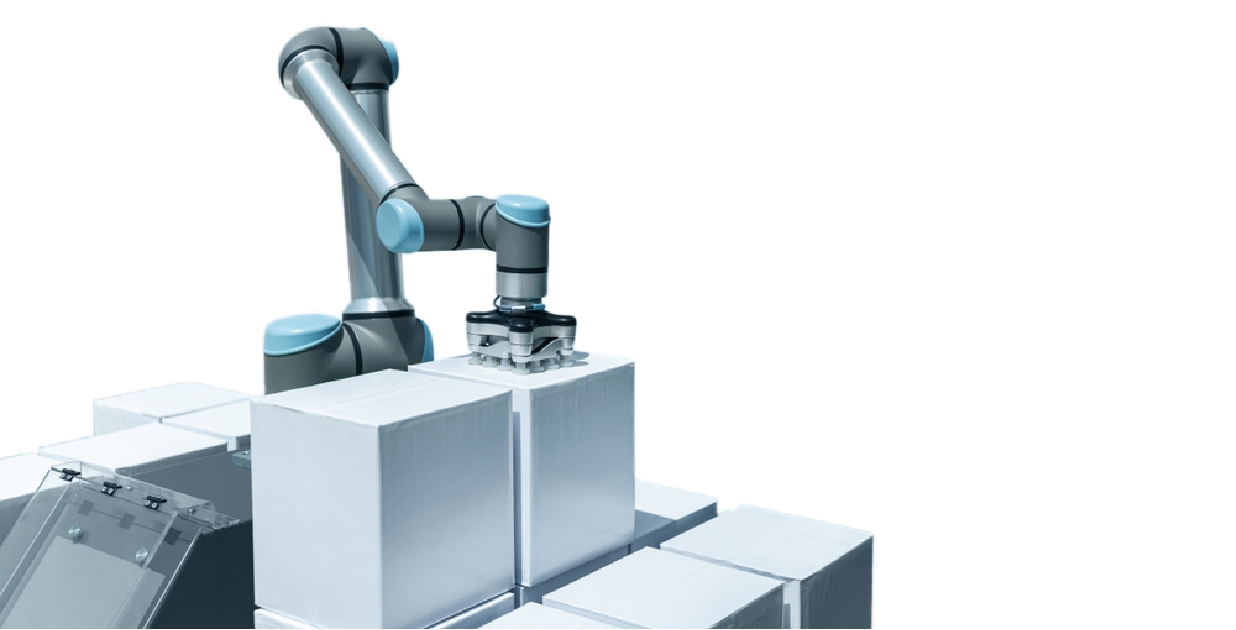

Palatalizing Robots

Cyber offers customizable solutions tailored to meet your specific requirements and space constraints.Whether you need to palletize products of different shapes, sizes, or weights, our robots can be adapted to suit your needs, ensuring optimal performance and efficiency.

Guaranteeing Product Integrity

By automating the palletizing process, our robots help increase production output, minimize labor costs, reduce product damage, and optimize warehouse space utilization. This translates to significant cost savings and improved operational efficiency for businesses in various industries. Additionally, our robots ensure the integrity of your products throughout the handling and shipping process, leading to higher customer satisfaction and fewer returns.

Streamline Packaging Operations with

Palatalizing Robotics

Palatalizing robots are the ultimate solution for optimizing packaging processes. These advanced machines automate palletization tasks, enhancing efficiency and accuracy. By integrating palatalizing robotics, businesses can cut labor expenses, accelerate warehouse operations, and stay ahead in today’s competitive market

UNLEASH EFFICIENCY

Palatalizing Robots Transform Packaging

Discover the future of packaging efficiency with palatalizing robots. These cutting-edge machines revolutionize the stacking process, ensuring precision and speed. By embracing palatalizing robotics, businesses can slash labor costs, expedite warehouse operations, and gain a competitive advantage in the market

Industries that Use Our Welding Robots

Our palletizing robots are versatile enough to handle various packaging materials, including boxes, bags, and containers, making them ideal for industries such as food and beverage, consumer goods, pharmaceuticals, automotive, chemicals, and logistics. Whether you’re palletizing products in a warehouse, distribution center, or manufacturing facility, our robots are engineered to streamline your operations

COMPLETED SOLUTIONS

ASSESSMENT AND PLANNING

SIMULATING AND PROGRAMMING

EXPERT MANUFACTURING AND FABRICATION

BEAM SAW MACHINE

INDUSTRIES THAT USED OUR ROBOTICS SOLUTIONS

AUTOMOTIVE INDUSTRY

LOGISTICS AND WAREHOUSING

METAL FABRICATION INDUSTRY

FOOD AND BEVERAGE INDUSTRY