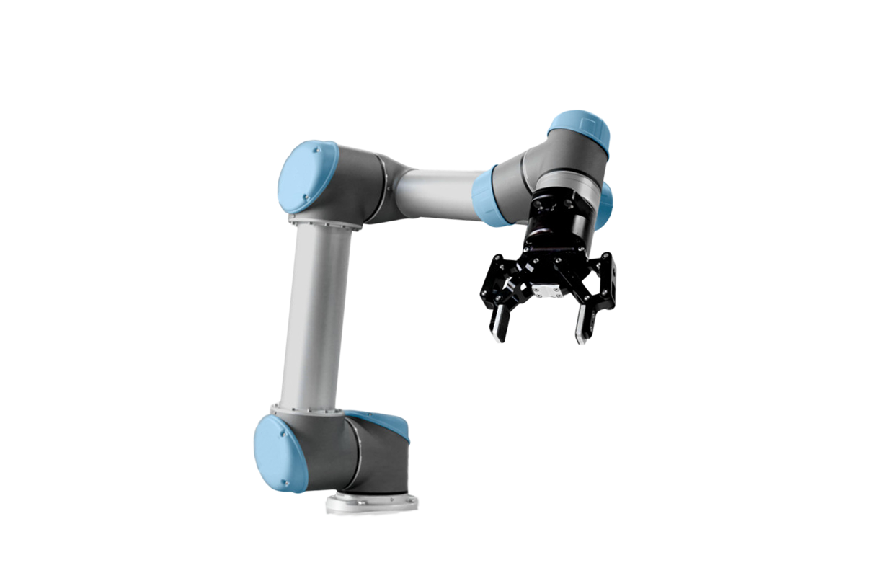

Machine Tender ROBOT

Precision Automation: Elevating Manufacturing With

Machine Tending Solutions

At cyber company, we recognize the critical role that machine tending plays in achieving these objectives. Our expertise lies in providing innovative solutions that streamline the process of loading and unloading materials into machines, thus maximizing throughput and minimizing downtime. With our advanced machine tending systems, businesses can unlock new levels of productivity, accuracy, and cost-effectiveness in their manufacturing operation.

Elevate Your Manufacturing Efficiency

In today’s dynamic manufacturing landscape, achieving competitiveness demands strategic optimization. Machine tending solutions offer a transformative approach, automating tasks to boost productivity, enhance precision, ensure safety, and drive cost savings. With unmatched flexibility and scalability, these systems empower businesses to stay ahead in the market, responding swiftly to customer demands and maintaining superior efficiency and quality.

The Role Of Machine Tending In Modern Manufacturing

Machine tending is an automated process involving the use of robotics and advanced control systems to load and unload materials into machines such as cnc machines, lathes, and milling machines. By automating repetitive tasks traditionally performed by human operators, machine tending systems optimize production efficiency, enhance precision, and ensure consistent quality. These systems integrate seamlessly into existing production lines, reducing cycle times, minimizing downtime, and improving overall operational effectiveness. With their ability to handle various work piece shapes, sizes, and materials, machine tending solutions offer unmatched versatility and adaptability to meet the evolving needs of modern manufacturing environments.

COMPLETED SOLUTIONS

ASSESSMENT AND PLANNING

SIMULATING AND PROGRAMMING

EXPERT MANUFACTURING AND FABRICATION

BEAM SAW MACHINE

INDUSTRIES THAT USED OUR ROBOTICS SOLUTIONS

AUTOMOTIVE INDUSTRY

LOGISTICS AND WAREHOUSING

METAL FABRICATION INDUSTRY

FOOD AND BEVERAGE INDUSTRY