A GUIDE TO GRIPPERS TOOL CHANGER

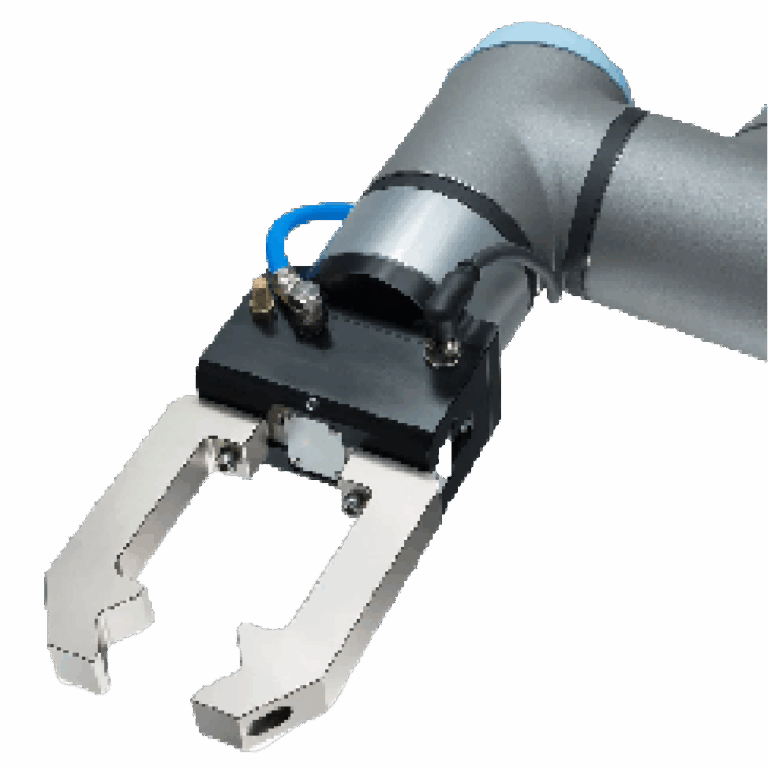

Pneumatic Grippers

Pneumatic grippers operate using compressed air to actuate its jaws (also known as fingers). They are known for their rapid response times and suitability for high-speed applications

Approximate Weight Carried By Pneumatic Grippers

The weight capacity of grippers can vary significantly depending on factors such as gripper type, size, design, and operating conditions Here’s a general range for the weight carried by pneumatic grippers

(10grams to 10 kilograms)

Pneumatic grippers are utilized in sectors such as manufacturing, automotive, electronics,

Packaging, food and beverage and for tasks including handling, sorting.

Pneumatic Grippers

Hydraulic grippers use hydraulic fluid to exert force, making them ideal for heavy-duty

Applications requiring significant gripping force.

Approximate Weight Carried by Hydraulic Grippers

The weight capacity of grippers can vary significantly depending on factors such as gripper

Type, size, design, and operating conditions

Here’s a general range for the weight carried by hydraulic grippers

(50 kilograms to 5 tons)

Hydraulic grippers

Hydraulic grippers are employed in sectors such as heavy machinery,construction, mining,

Steel fabrication, and for tasks involving heavy-duty gripping, lifting, and positioning

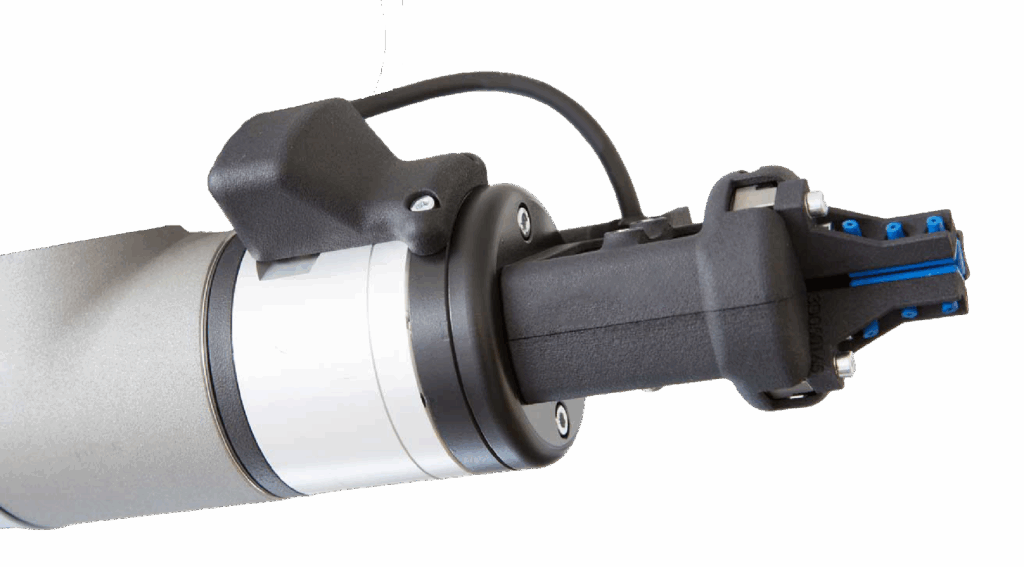

Electrical Grippers

Electric grippers, favored in cobot tasks like machine tending and pick & place, prioritize speed over grip strength. They commonly come in two or three-jaw designs, with the latter preferred for handling round objects

Approximate Weight Carried by Electrical Grippers

The weight capacity of grippers can vary significantly depending on factors such as gripper

type, size, design, and operating conditions

Here’s a general range for the weight carried by Electrical Grippers

(5 grams to 50 kilograms)

Electric grippers find applications in sectors such as robotics, manufacturing, electronics,

food processing, and packaging for tasks including assembly, sorting, pick & place,

and delicate object handling

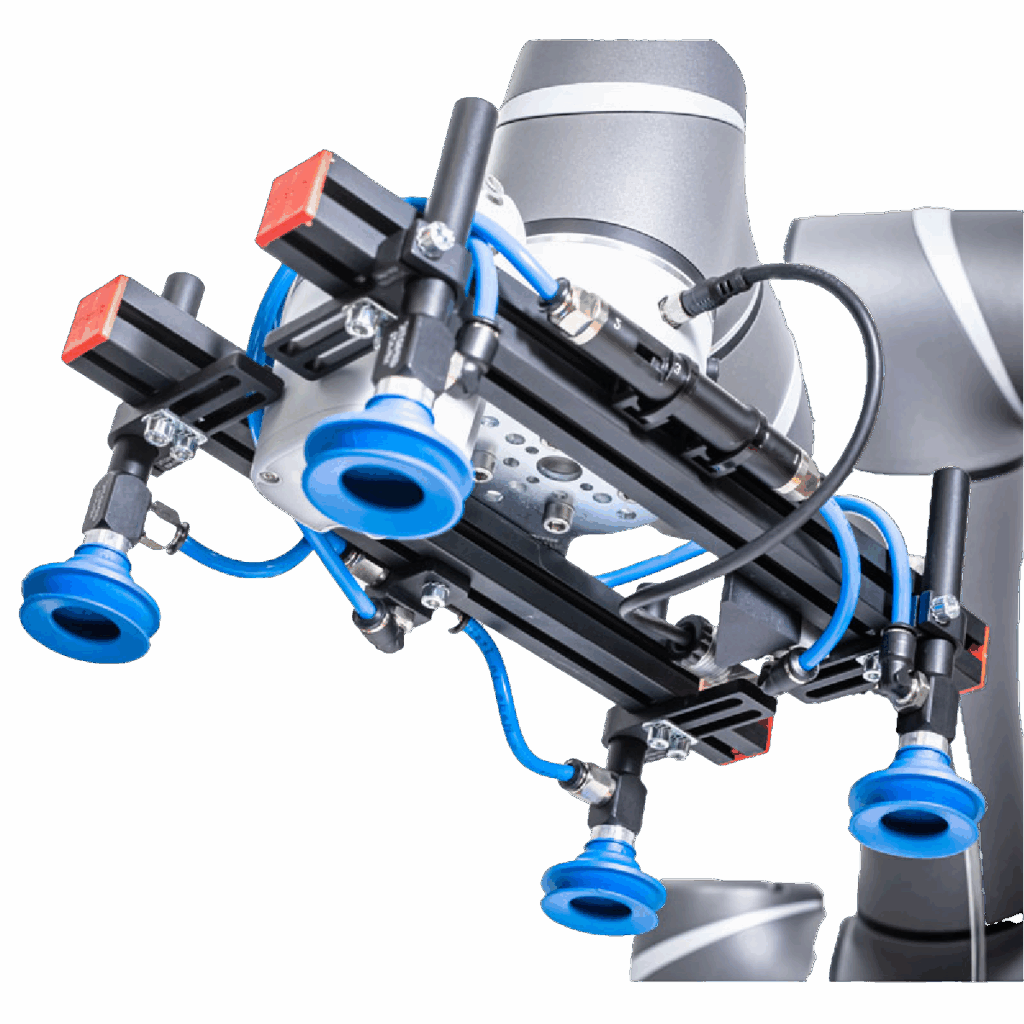

VACUUM GRIPPERS

Vacuum grippers use suction to hold objects securely. They are suitable for handling flat or

Non-porous objects such as sheets of glass, metal, or plastic

Approximate Weight Carried by Vacuum Grippers

the weight capacity of vacuum grippers can vary depending on the specific model and

application. However, a typical range for the weight carried by vacuum grippers is

approximately 0.1 kg (100 grams) to 50 kg, with some specialized grippers capable of

handling even heavier loads

Vacuum grippers are utilized in industries such as packaging, logistics, manufacturing,

and robotics for tasks including picking, placing, palletizing, and handling flat or non-porous

objects like boxes, sheets, glass, and plastic

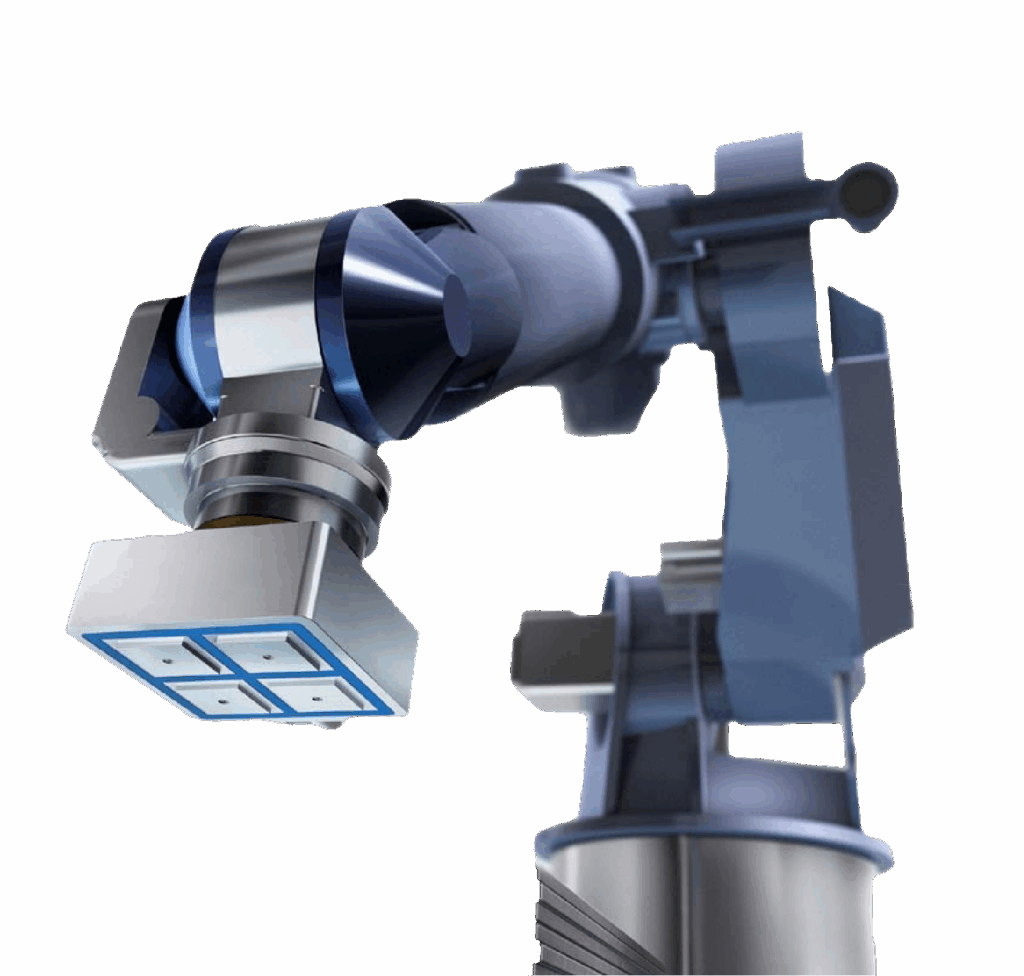

MAGNETIC GRIPPERS

Magnetic grippers utilize magnetic force to grip ferrous objects. They are often used in

applications where traditional gripping methods may not be feasible.

Approximate Weight Carried by Vacuum Grippers

The weight carried by magnetic grippers typically ranges from approximately

0.1 kg (100 grams) to 100 kg, depending on their size, design, and magnetic strength

Magnetic grippers use a magnetized surface to grab the metal items.

Magnetic grippers are most common in industries where sheet metal and automotive parts

are moved along an assembly line, manufacturing, automotive, robotics, metalworking,

and recycling for tasks including material handling, part manipulation, picking and placing

ferrous objects, and sorting operations

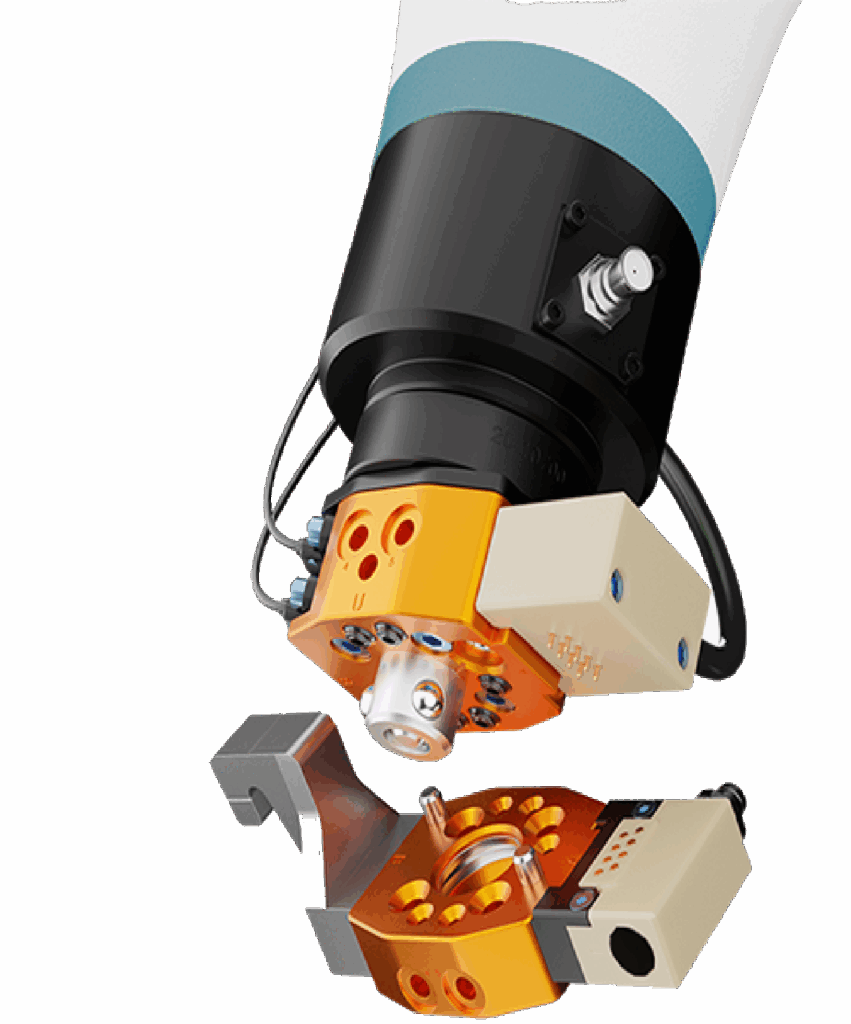

WHAT IS A ROBOTIC TOOL CHANGER

/ QUICK CHANGER (QC)?

A Robotic Tool Changer (QC) is an end-effector comprising two parts, Master-side and Tool-side, designed to automatically lock together, carry payloads, and transfer utilities. It enables quick tool changes in automated processes, attaching to robots or CNC machines on the Master-side and various tooling on the Tool-side.

WHAT IS A ROBOTIC TOOL CHANGER

/ QUICK CHANGER (QC)?

A Robotic Tool Changer (QC) is an end-effector comprising two parts, Master-side and Tool-side, designed to automatically lock together, carry payloads, and transfer utilities. It enables quick tool changes in automated processes, attaching to robots or CNC machines on the Master-side and various tooling on the Tool-side.

MAGNETIC GRIPPERS

Magnetic grippers utilize magnetic force to grip ferrous objects. They are often used in

applications where traditional gripping methods may not be feasible.

Approximate Weight Carried by Vacuum Grippers

The weight carried by magnetic grippers typically ranges from approximately

0.1 kg (100 grams) to 100 kg, depending on their size, design, and magnetic strength

Magnetic grippers use a magnetized surface to grab the metal items.

Magnetic grippers are most common in industries where sheet metal and automotive parts

are moved along an assembly line, manufacturing, automotive, robotics, metalworking,

and recycling for tasks including material handling, part manipulation, picking and placing

ferrous objects, and sorting operations